|

Mixing Slip

When mixing slip there are a few considerations to take into effect: Start with about 5 % warm water. Add your deflocculant to the warm water. Because the defocculant is likely to be less then 1% of the recipe, it is important to measure it carefully either by weight or by volume. Beginning with the lightest ingredient mix ingredients one at a time to avoid pancaking later. Every clay/slip will have a clay, a flux (melting agent), a glass maker, and most likely has a filler. Sometimes ingredients will do double duties. Kaolins (porcelains) will be lightest, ball clays next, other clays next, then things like talc, silica, and feldspars are likely to be the heaviest. You can do a simple touch test to determine density. Sieve and add water to get to desired consistency based on your needs. I recommend double sieving at about a 40/60 and 80/100. When recycling slip, its best to dry it out completely then add warm water and double sieve. If you have used a Darvan as your deflocculant, you will not need to add more. If you have used sodium silicate, recycle your slip as above, then test the webbing properties. If it is not webbing properly, add sodium silicate a tiny drop at a time. Go slow with this and be careful not to add too much water until the deflocculation is complete. To avoid this, use a Darvan. Tips: Over deflocculation and under deflocculation look almost the same. Vinegar will cut deflocculation, go slow and if in doubt, revisit it the next day. I have found that slip is best after sitting for a day.

0 Comments

Mold Making 3 things to consider: What is the material the positive is made from? Is it porous, non- porous, and will the heating of the plaster possibly cause and expansion? What does the object look like- does it have undercuts or details that are important to maintain? What is your plan with the final objects? Do you need the objects to be soft for further modification? If so, you may need additional parts of the mold for easy release. 1. Decide if you want to use a clay bed to lay your object on or if you want to lay it directly on the surface (the clay bed is easier to seal. 2. Soap your object if porous. Polish it to a silky finish. 3. Determine where your walls need to be for each section before you start. This will ensure that you are working smart not hard. Use a clay maquette or a sketch to help you. If you don’t care about the object you can also use a sharpie directly on the object. 4. Using slabs, create walls for each section. Be careful to seal each section (rubber finger tools work great for this.) Mix and pour plaster one section at a time. Let each section set up. Make keys, then pour the next section. 5. Use the amount of clay it takes to properly caulk any cracks. Wipe away any extra clay. A small amount of clay can seal without creating a large seem. 6. After the mold has been poured and has set, gently vibrate the mold apart. Remove the positive. Put the mold back together for cleaning so that you don’t inadvertently clean the fettle lines (the place where the mold pieces meet up on the interior of the mold. ) Sanding the mold compresses the mold, gets rid of plaster that might chip off, and helps it to last in the future. Slip: Even store bought slip should be sieved before use. This eliminates lumps that will have to be sanded out later and allows even water distribution. Deflocculate: To literally break up the “flock” of clay particles by creating a negative charge and causing particles to repel each other. This allows us to add less water with more fluidity and allows particles to bond with better compression and with out air bubbles. We add this deflocculant to slip (Darvan or Sodium Silicate) Coddle: The objects which contain our plaster while it sets around the object we are casting. Sometimes Aluminum Flashing, or boards we clamp together. Fettle: The seam of the mold. Fettle Line: The line of an object where the undercut occurs (often still visible on plastic cast objects, such as pens) Undercut: The point where if an immoveable object (such as set plaster) is wrapped around it will become locked and cannot be removed. Key: the small indentation that keeps a mold from sliding apart. Two primary types: Standard Keys and Slide Keys. Plaster 101

What is plaster: Plaster comes from a naturally occurring mineral state. Pottery Plaster #1 is a Gypsum based plaster. When it is heated to about 300 degrees f it becomes a powder. The water of crystallization has been removed. When you re-hydrate the material, the molecules are able to take up this water, and form new inter-locking crystals. This we recognize as set plaster. These interlocking crystals are a chemical reaction and create a sponge like quality that work to absorb the moister from clay. Heat and cold will break down this structure. In order for plaster to have the relationship with clay that we want, it is important that it is mixed in a way that the correct crystalline structure is developed. To Mix: Make sure the plaster feels soft and powdery (if there are hard lumps it may have been exposed to moisture) Measure a little less water then you think will fill up the area you want to cover Slake the plaster into the water, not too slow, not too fast-breaking up any lumps as you go watch for the chemical reaction to occur where the plaster starts to sit on the surface of the water (not just a lump in the middle of the plaster) Let plaster sit in water 2-3 minutes Agitate until you can see a finger trail in the slip that disappears quickly Mist with rubbing Alcohol to pop bubbles Pour steadily into your mold, trying not to create air bubbles Agitate the mold Mist with rubbing Alcohol to pop bubbles You can release carefully when warm or after warmth has cooled (anywhere from 20 min- 1hour) Wet sand to clean up and compress plaster. "Magic" SlipTo make slip that is good for patch/repairs, slip trailing or more. Take the same clay body and dry it to a bone dry state. Add warm water and dip your finger into Darvan 7 (defloculant) about two times and swish it in the slip. The slip should have a slightly oily look. You can also add a little paper pulp if you want to.

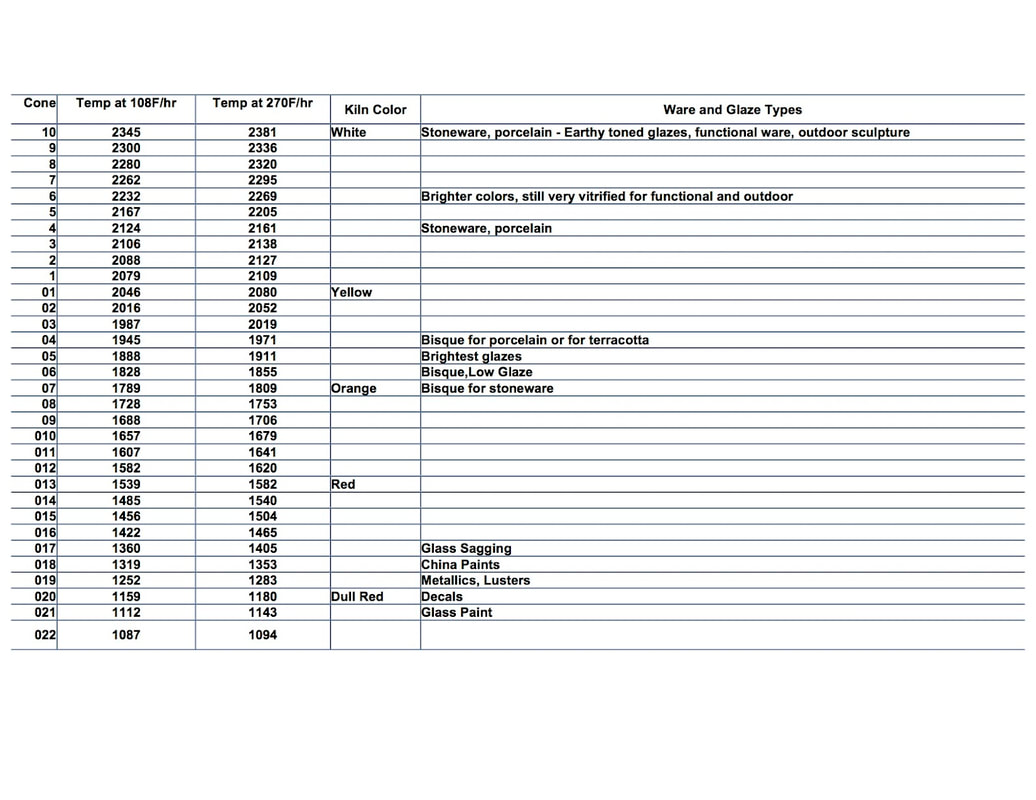

ConesCone Temperatures 10 (High fire) 9 8 7 6 (Mid) 4 3 2 1 01 02 (high bisque) 03 04 (low fire) 05 06 07 08 09 010 (low bisque) ... 018 019 020 (Enamle, Luster, China) Sources for information on materials-http://lindaarbuckle.com/arbuckle_handouts.html

http://lindaarbuckle.com/handouts/vocabulary-basic-ceramics.pdf http://digitalfire.com Things that are good to have:There is a lot of stuff on this list. You definitely need some of your own tools.

Household Items are a great place to start: Forks, containers with lids, rolling pins, cutting boards, anything that seems useful. You probably want the sand paper. You need a respirator. The rest of what you need depends on how much you like to work on your own and how much you will be doing in the future. Here are some of my favorites:

|

AuthorTL Nelson, MFA; ArchivesCategories |

|

|

All Images and content Copy Written. Use of images only permitted for promotion and education and must be credited properly with the website link. Thank you. (NOTE: Date imbedded in Images)

|

RSS Feed

RSS Feed